Discover the Virtuosity of In-Mold Decorations in Production

Wiki Article

Grasping In-Mold Decorations: Methods, Patterns, and Ideal Practices for Ideal Outcomes

In the realm of production, the art of in-mold decorations stands as a crucial element of product style and manufacturing. As industries consistently seek ingenious means to improve aesthetic charm and capability, understanding the ins and outs of in-mold decorations has become a vital ability. From selecting the appropriate materials to integrating sophisticated design patterns, the trip in the direction of achieving ideal lead to this domain is multifaceted. By delving into the approaches, trends, and finest methods that underpin effective in-mold decoration processes, organizations can unlock a world of opportunities that not just elevate the aesthetic appeal of their items however likewise simplify manufacturing efficiency and reinforce consumer interaction.Material Selection

Material choice is a crucial facet of grasping in-mold decorations, as it straight impacts the high quality and resilience of the last product. When picking materials for in-mold decors, it is important to take into consideration elements such as compatibility with the molding procedure, the desired visual outcome, and the ecological problems the product will certainly face.Additionally, the selected material needs to possess great attachment properties to guarantee that the decor adheres securely to the substratum during the molding process. Bond in between the material and the design is important for protecting against delamination and guaranteeing resilient aesthetic appeal. Furthermore, products with high warmth resistance are preferred for in-mold designs, particularly for items that will certainly be revealed to raised temperatures during their lifecycle. By very carefully picking the appropriate material for in-mold decorations, producers can improve the total top quality and resilience of their products, meeting the expectations of both end-users and clients.

Layout Innovation

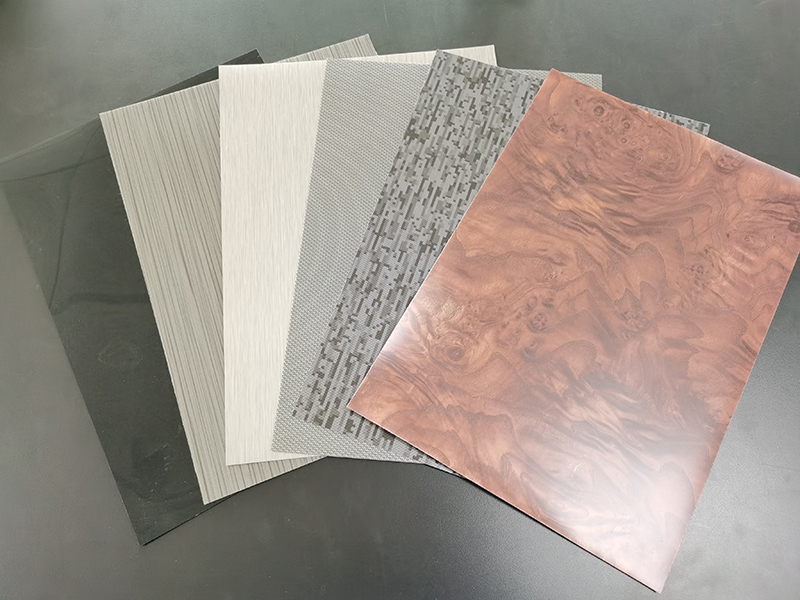

An essential factor in progressing the area of in-mold designs is the constant exploration and implementation of design technology strategies. Layout advancement plays an important function in enhancing the visual charm, performance, and overall quality of items produced using in-mold decor procedures. By integrating innovative layout aspects, producers can differentiate their products in the marketplace, draw in consumers, and remain ahead of competitors.Among the essential aspects of layout development in in-mold decorations is the assimilation of elaborate patterns, textures, and graphics that were formerly challenging to attain with conventional decor techniques. Advanced technologies such as 3D printing and electronic design devices enable developers to create facility and comprehensive layouts that can be perfectly moved onto molded components. Additionally, making use of vibrant shades, metal surfaces, and unique effects like gloss or matte structures can further raise the aesthetic appeal of in-mold enhanced items.

Additionally, layout development prolongs past looks to encompass practical improvements such as ergonomic shapes, integrated attributes, and customizable elements that accommodate certain customer needs. By welcoming design technology, manufacturers can unlock brand-new opportunities for personalization, product, and imagination distinction in the affordable landscape of in-mold decors.

Manufacturing Performance

Effective production processes are crucial for converting the ingenious designs developed in the area of in-mold designs into high-quality ended up items that meet market needs and consumer assumptions. In the realm of in-mold decorations, manufacturing effectiveness encompasses numerous crucial aspects that add to the general success of the manufacturing procedure.Additionally, implementing automation and robotics in the assembly line can substantially improve performance by improving repetitive jobs and reducing the margin of mistake. Automation not only increases the manufacturing process yet likewise boosts accuracy and repeatability, leading to a more top notch and uniform final product. Moreover, adopting lean manufacturing concepts, such as just-in-time inventory monitoring and waste reduction methods, can further improve manufacturing efficiency by decreasing downtime and optimizing source application. On the whole, a holistic technique to manufacturing efficiency is critical in making the most of the capacity of in-mold design strategies and achieving ideal lead to the open market landscape.

High Quality Control Procedures

What are the vital strategies for guaranteeing stringent high quality control measures in the realm of in-mold decors? Quality control procedures are paramount in in-mold decor processes to make certain the production of premium and flawless ended up products.Using advanced innovations such as computerized inspection systems can likewise enhance the high quality control procedure by offering accurate and reputable data for analysis. These systems can find blemishes that may be missed out on by hand-operated evaluations, therefore improving general item helpful hints quality and uniformity.

Regular training and advancement programs for staff members involved try this website in the in-mold design procedure can additionally contribute to preserving high-quality requirements. By informing team on best practices, high quality expectations, and the importance of attention to detail, business can cultivate a society of top quality consciousness throughout the company.

Customer Allure

To enhance the bankability of in-mold design products, recognizing and catering to consumer choices play a crucial role in establishing their charm and success. Offering modification choices such as personalized styles, shade variations, and textural elements can significantly boost the charm of in-mold decoration items.

Final Thought

In-mold designs provide a versatile and efficient way to improve product looks. Mastering in-mold decors calls for an alternative method that considers all facets of the production process to ensure success.In the world of production, the art of in-mold decorations stands as a pivotal facet of product design and manufacturing. Design innovation plays a critical function in enhancing the visual see this site charm, functionality, and total high quality of items produced using in-mold design processes.One of the vital elements of layout advancement in in-mold decorations is the assimilation of elaborate patterns, appearances, and graphics that were previously testing to accomplish with typical design approaches.Effective manufacturing processes are crucial for equating the cutting-edge designs created in the field of in-mold designs right into premium ended up products that fulfill market demands and consumer assumptions. Offering personalization alternatives such as customized layouts, color variations, and textural aspects can significantly improve the allure of in-mold decoration products.

Report this wiki page